Post #21

|

Wednesday, 15-Feb 2017 @ 8:25pm

considered something like that, but it woud mean the engine would have to sit higher. then the turbo wouldn't fit, so the engine would have to go even further back... At this stage i think i'll already be moving the pedals back 20mm to clear the dump pipe off the turbo.

I do like the tube frame tunnel idea, it will make fabricating the exhaust a lot easier then laying on my back under the car. plus it will make pulling the gearbox and engine so much easier.

Engineer is happy to put it through as being turbo (ie needs to meet his requirements for adding a turbo) without installing the turbo so it doesn't have to be engineered again.

You have no idea how tempting it is to put the t25 i already have on it and call it a day, but i'm interested to see what the 6 port motor can do given it's large standard ports. The equivalent sinlge circle diameter (measured at the intake manifold flange) is just over 55mm, with port timing similar to a late opening PP. But with the ability to control the opening of the aux ports it will still have low and mid range torque, with a sacrafice of a bit top end due to the intake not being on the peripheral.

Given that people get around 160-170rwhp out of a 6 port (no major porting, just a clean up and change to turbo centre plate) and how small the centre plate (compared with 6 port end plates) is i'm hoping to get about 85-100rwhp with it na before porting. Although given the stock port timing this will likely occur around the 8-9000rpm mark. I'm hoping a 4.7ish diff with the rx8 6 speed gearbox should help to get it up to revs quickly, when combined with some 9.7:1 lightened rotors.

I'm hoping for similar power to a standard NA 1.6 MX5, but being in a~400kg lighter chassis. The mx5 i used to have was good fun through the hills of adelaide, with just enough power to not get you in too much trouble, but enough to have a bit of fun. I think on a track it's limits would have been similar to mine (on street tyres), but my limits were the limiting factor through the hills.

I had a lot more fun with the MX5 off the track then my 180sx as i knew i could rev it that bit harder without going past my limits. In the 180sx, even on low boost (14psi) and only making a bit over 200rwhp, hitting too much boost at the wrong part of the corner would have the back end come out, hence my hesitation to drive it to it's potential off the race track. I'm sure the 2 way diff, rose-jointed everything, stiff coilovers and solid mounted engine, diff and gearbox didn't help on the bumpy eneven roads...

If you really advise to go down the turbo route straight away (from experience driving both NA and turbo single rotors), I'll look into running a low boost turbo (as you suggested) for around 120rwhp or so. What turbo would you recommend for this application?

I'll still keep the 6 port arrangement though as i believe i need to focus on getting the best 'area under the curve' power until i get used to the set-up (both lightweight chassis, high revving rotary, as well as getting gearing sorted out)

I agree a PP would be the best set-up overall for a turbo rotary. When PPing it I would rather invest in alloy end plates rather then fill the standard ports and I don't have the budget to do this yet, plus they won't pass engineering. Once engineered though, they could easily be swapped and no one will know...

I do like the tube frame tunnel idea, it will make fabricating the exhaust a lot easier then laying on my back under the car. plus it will make pulling the gearbox and engine so much easier.

Engineer is happy to put it through as being turbo (ie needs to meet his requirements for adding a turbo) without installing the turbo so it doesn't have to be engineered again.

You have no idea how tempting it is to put the t25 i already have on it and call it a day, but i'm interested to see what the 6 port motor can do given it's large standard ports. The equivalent sinlge circle diameter (measured at the intake manifold flange) is just over 55mm, with port timing similar to a late opening PP. But with the ability to control the opening of the aux ports it will still have low and mid range torque, with a sacrafice of a bit top end due to the intake not being on the peripheral.

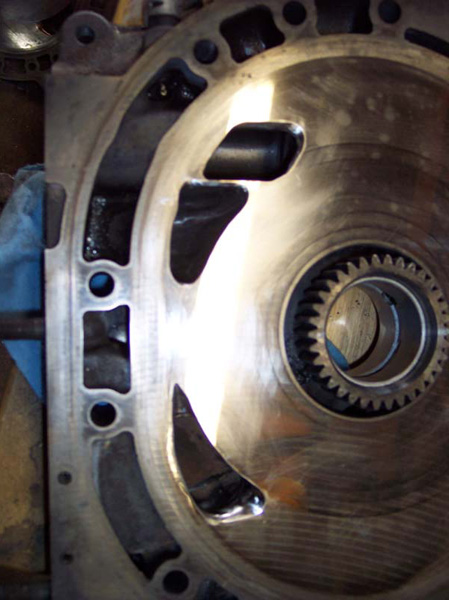

Given that people get around 160-170rwhp out of a 6 port (no major porting, just a clean up and change to turbo centre plate) and how small the centre plate (compared with 6 port end plates) is i'm hoping to get about 85-100rwhp with it na before porting. Although given the stock port timing this will likely occur around the 8-9000rpm mark. I'm hoping a 4.7ish diff with the rx8 6 speed gearbox should help to get it up to revs quickly, when combined with some 9.7:1 lightened rotors.

I'm hoping for similar power to a standard NA 1.6 MX5, but being in a~400kg lighter chassis. The mx5 i used to have was good fun through the hills of adelaide, with just enough power to not get you in too much trouble, but enough to have a bit of fun. I think on a track it's limits would have been similar to mine (on street tyres), but my limits were the limiting factor through the hills.

I had a lot more fun with the MX5 off the track then my 180sx as i knew i could rev it that bit harder without going past my limits. In the 180sx, even on low boost (14psi) and only making a bit over 200rwhp, hitting too much boost at the wrong part of the corner would have the back end come out, hence my hesitation to drive it to it's potential off the race track. I'm sure the 2 way diff, rose-jointed everything, stiff coilovers and solid mounted engine, diff and gearbox didn't help on the bumpy eneven roads...

If you really advise to go down the turbo route straight away (from experience driving both NA and turbo single rotors), I'll look into running a low boost turbo (as you suggested) for around 120rwhp or so. What turbo would you recommend for this application?

I'll still keep the 6 port arrangement though as i believe i need to focus on getting the best 'area under the curve' power until i get used to the set-up (both lightweight chassis, high revving rotary, as well as getting gearing sorted out)

I agree a PP would be the best set-up overall for a turbo rotary. When PPing it I would rather invest in alloy end plates rather then fill the standard ports and I don't have the budget to do this yet, plus they won't pass engineering. Once engineered though, they could easily be swapped and no one will know...

Cheers

Luke

Luke

1967 Datsun B10 2 Door.

1967 Datsun B10 2 Door.