Post #14

|

Monday, 17-Oct 2011 @ 10:05pm

Edited by

ratb10

Monday, 17-Oct 2011 @ 10:21pm

Thanks for the help, I have a 1200 mount on one side so that should be sweet. The other side I have an orginal 1000 mount, I'll have to see if I can fit a bolt since there is that angled metal piece in the way.

I also have some square tube so I might try and run solid mounts anyway.

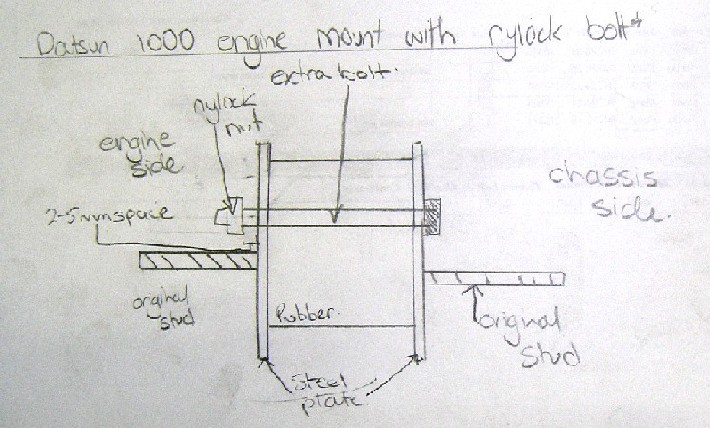

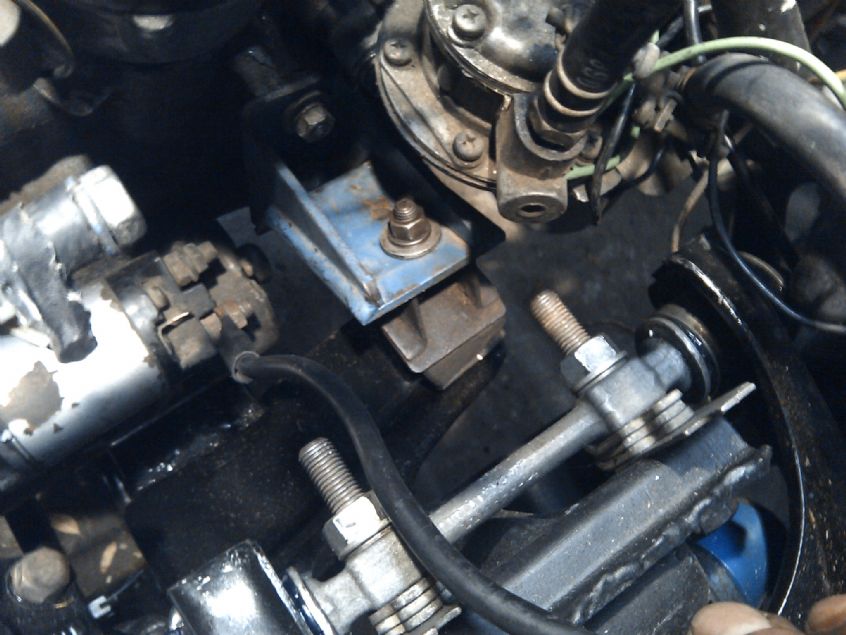

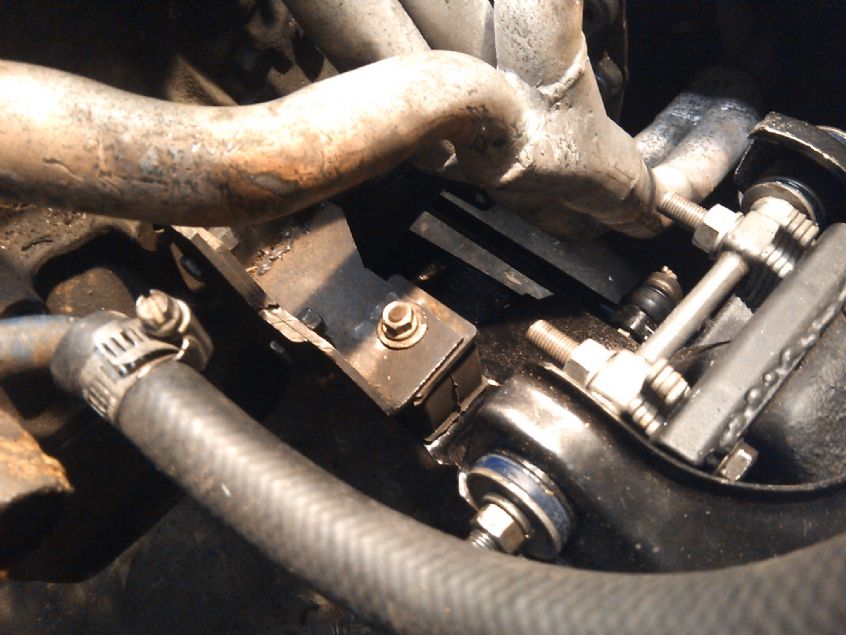

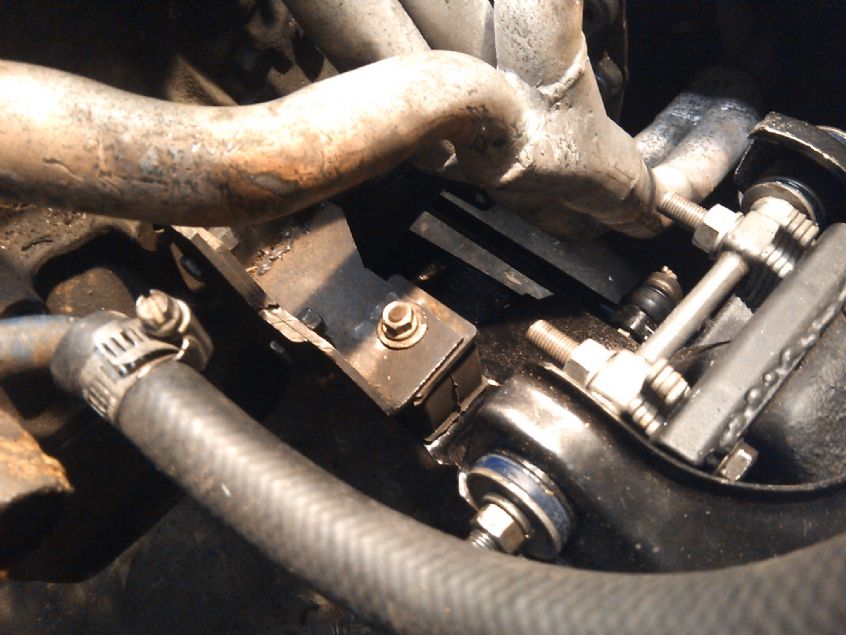

Here is a pic mounting up a 120y a12 for those that need help fitting a later model engine.

The LHS side is original 1000 rubber combined with the 120y section.

RHS is a couple of angles, in the shape replicating the 120y mount but flat bottomed so it has a 1200 mount underneath. I think the original 1000 rubber would work with the stock 120y mount if I had one (not sure how this is possible?)

This setup is not finished however, I need to drill some iron strap to move the engine back a little. I haven't measured this up yet, the tailshaft I have is to suit a h150 (maybe 10 or 15mm longer than the 1000 shaft) and it requires some movement in the back of the gearbox.

1967 Datsun B10 2 Door.

1967 Datsun B10 2 Door.