|

|

|

|

Reference Material |

|

|

|

|

Hub, Front

Dismantling the Front Hub

To dismantle the front hub, first jack up the car until the wheel is clear of the ground and then place a stand under the side member.

Jack down the car on the stand.

Remove the wheel. If the drum appears to hold on the brake shoes, the shoe adjusters should be slackened. Take off the hub cap by a lever, and then extract the split pin from the spindle nut.

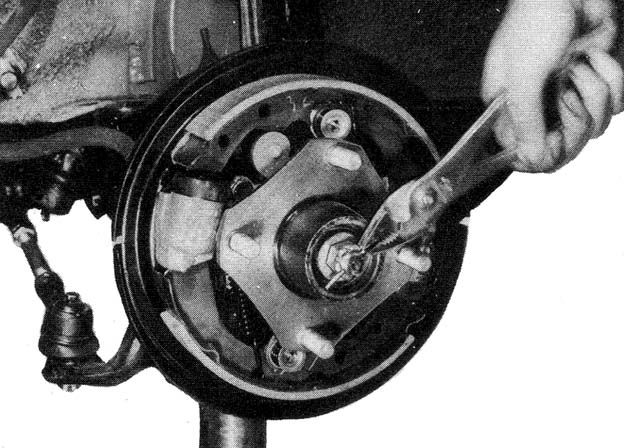

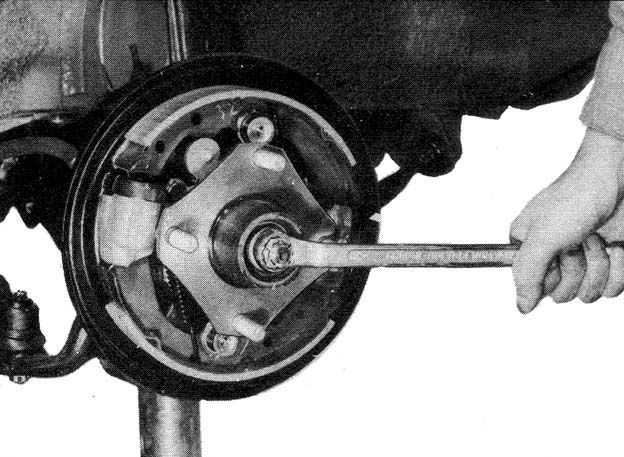

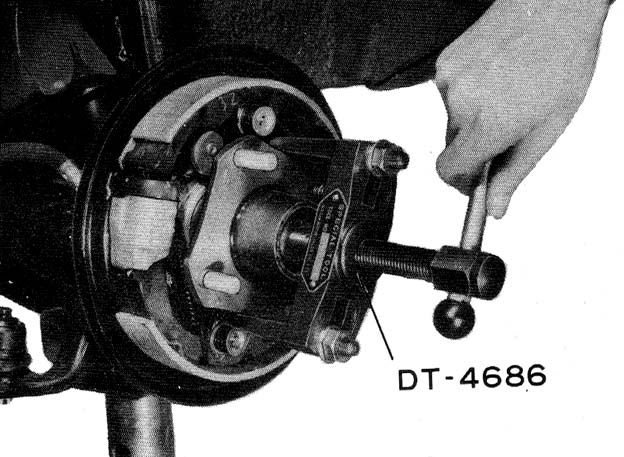

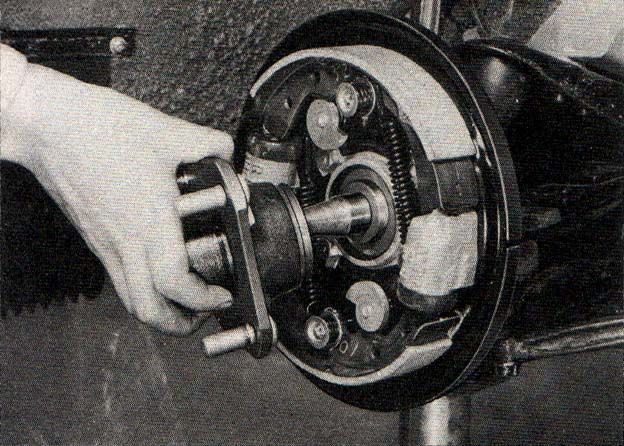

Using a box spaner, remove the spindle nut and the flat washer under it, extract the road wheel hub with the bearing from the knuckle spindle by the puller.

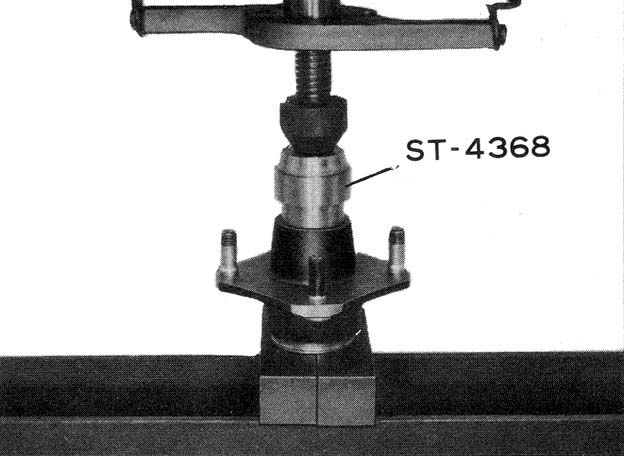

After the hub has been removed, the bearings can be dismantled. The inner bearing and oil seal can then be removed by inserting the drift from the opposite side of the hub.

Assembling the Wheel Hub

When assembling the inner bearing cone to the hub sufficently smear grease to the inner face of wheel hub.

Assemble the wheel bearing to the wheel hub.

Pack the hub with reccomended grease.

| Grease Brand | Shell Oil Co. | Mobil Oil Co. | Esso | Caltex Oil Co. | Gulf Oil Co. |

|---|---|---|---|---|---|

| Grease Type | Shell Retinax A (Li) | Mobil Grease MP (Li) | Esso Multipurpose Grease (Li) | Caltex Marfak Multipurpose 2 (Li) | Gulfex A (Li) |

Replace the hub oil seal over the inner bearing.

Renew the seal if it is damaged.

Adjusting Pre-Load of Wheel Bearings

| Tightening Torque of Spindle Nut |

|

|---|---|

| 1.6 - 1.8kg-m |

If Lubricated on the face of Screw and Washer |

| 2.3 - 2.5kg-m |

Without Lubrication |

Rotating thw wheel hub several times for setting smoothly, and then again tighten the nut with the aforesaid torque.

| Torque for Rotation of beginning |

| 25 - 30 kg-cm |

Fit the pin hole with the spindle nut within 40°-70° degree turning back around the nut.

Again rotating the wheel hub,make sure asto beginning torque for rotation and end play for horizontal way along the spindle.

- Torque of beginning for rotation, Less than 9 kg-cm

- End play for horizontal way along the spindle, Under 0.08mm

Lock the spindle nut by the cotter pin and lock washer after final adjustment for preload.